Airlift fermenter: suitable for fermentation types with high oxygen consumption and microbial cells that are not resistant to stirring and shearing. Airlift fermenters have significant advantages in cultivating filamentous bacteria such as Streptomyces, actinomycetes, fungi, etc., mainly reflected in their low shear force, good oxygen transfer, and fluid mixing characteristics. The following are specific applications and advantages of it in filamentous bacterial culture:

Application background

Filamentous fungi, commonly known as molds, can produce mycelium, which is divided into basal hyphae and aerial hyphae. Aerial hyphae grow to a certain stage and differentiate to produce reproductive hyphae, which then produce spores. The morphological characteristics of fungal hyphae (especially reproductive hyphae) and spores are important criteria for identifying different types of fungi. Filamentous bacteria are a type of microorganism widely used in biopharmaceuticals, food fermentation, and industrial enzyme production.

They usually grow in the form of branched mycelia and are highly sensitive to shear forces. Traditional mechanical agitation fermentation tanks may cause mycelial breakage and morphological changes, affecting product quality and yield.

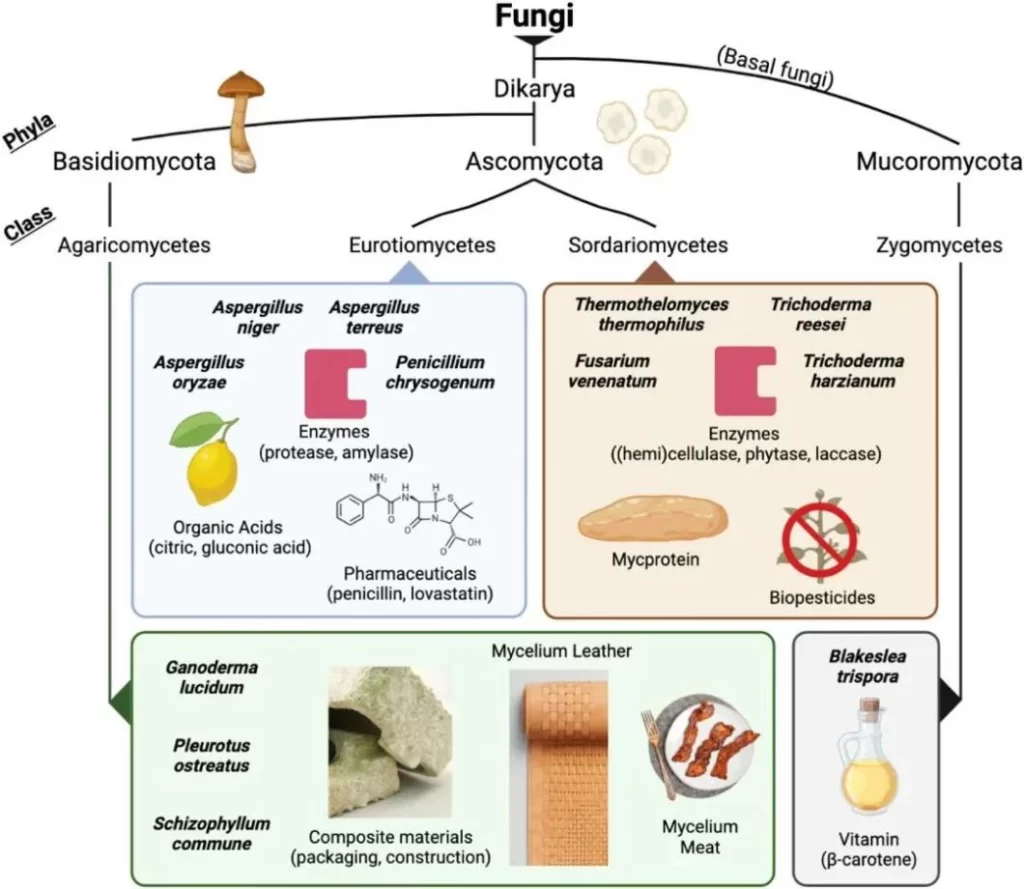

Famous industrial filamentous fungal host species and their related products

Application of filamentous fungal biomanufacturing and sustainable development

Since the development of biomanufacturing, many primary extracellular metabolites derived from filamentous fungi have been extracted to support various fields such as food, textiles, agriculture, animal health, bioenergy, and bioremediation. Due to the lack of a digestive system, fungi and mushrooms secrete various catabolic enzymes around their mycelium to hydrolyze carbohydrates, proteins, and lipids from other organisms, converting them into smaller molecules that are then transported to cells.

For example, white rot fungi secrete several lytic enzymes to attack organic matter rich in plant derived cellulose and lignin, cutting high molecular weight lignocellulose into shorter fragments. These hydrolysis and oxidase enzymes play an important role in carbon and nitrogen assimilation and are considered to be the basic reagents for generating primary metabolites (such as amino acids, organic acids, nucleosides) that are crucial for the growth of organisms.

Due to the high yield, simple cultivation methods, and synchronous biomass production in industrial fermentation processes, filamentous fungal derived enzymes account for more than half of the industrial enzyme market, especially in the food and beverage industry, reaching as high as 82%. The established industrial main species include Aspergillus niger (citric acid, gluconic acid, CAZymes), Penicillium flavum (penicillin), Aspergillus oryzae (amylase, pectinase), Trichoderma reesei (cellulase), and thermophilic mycelium.

Advantages of Airlift Fermenter (for filamentous bacteria)

| Characteristic | Describe |

| Low shear force | No mechanical stirring, relying solely on gas driven circulation to avoid damage to the mycelium |

| Higher oxygen transfer efficiency | Bubbles come into full contact with the culture medium during their ascent, which facilitates aerobic growth of filamentous bacteria |

| Good fluid circulation | Drive fluid circulation through density differences to promote uniform distribution of nutrients and metabolites |

| Easy to enlarge and perform aseptic operations | Simple structure, suitable for industrial production, easy to achieve aseptic control |

| Controllable morphological regulation | Suitable for controlling the spherical aggregation or dispersion state of filamentous bacteria, thereby optimizing product synthesis (such as antibiotics, enzymes, etc.) |

Typical application examples

Streptomyces spp.: used for the production of antibiotics such as tetracycline and streptomycin. Airlift tanks can control the size of mycelial aggregation and increase yield;

Actinobacteria spp.: produce various active metabolites, such as anticancer drugs, enzymes, etc;

Fungi (such as Aspergillus and Penicillium): ferment to produce citric acid, penicillin, and industrial enzymes (such as cellulase);

The airlift fermenter can reduce the risk of foam generation and pollution.

The basic steps and key control points for cultivating filamentous bacteria in an airlift fermenter:

1、 Preparation stage

- Preparation of bacterial strains

Select high-yield strains of target filamentous bacteria (such as Streptomyces for antibiotic production)

Obtaining seed liquid with strong vitality and uniform morphology through pre cultivation in shake flasks

- Preparation of culture medium

The composition of the culture medium should meet the growth and product synthesis needs of filamentous bacteria, usually including carbon sources (such as glucose), nitrogen sources (such as soybean meal hydrolysate), trace elements, etc

- Sterilization and Aseptic Operations

Fermentation tanks, culture media, air pipelines, etc. require high-temperature sterilization

The operation should be carried out under sterile conditions to avoid contamination

2、 Vaccination and cultivation stage

- Vaccination

Inoculate the seed liquid into the fermenter in a certain proportion (such as 5-10% v/v)

An appropriate amount of defoamer can be added during inoculation to prevent foam accumulation

- Ventilation start-up (principle of air lift)

Open the bottom air distributor (sparrow) and introduce sterile air

Air promotes the formation of circulation in the culture medium during the rising process (through the riser and downcomer)

3、Cultivation condition control (key)

| Parameter | Control range | Describe |

| temperature | Usually 28-32 °C | Suitable for most filamentous bacteria |

| pH value | Mostly ranging from 6.5 to 7.5 | According to the strain adjustment, it can be automatically adjusted |

| dissolved oxygen | >30% (saturated dissolved oxygen) | By adjusting the ventilation rate or supplementing oxygen |

| Gas flow rate | 0.5–1.5 vvm | Promote circulation and increase oxygen transfer rate |

| Foam control | Add defoamer or foam probe | Filamentous bacteria are prone to producing bubbles and require close monitoring |

1、 Morphological regulation of filamentous bacteria (key impact on yield)

Agglomerated mycelium vs dispersed mycelium

Small and uniform bacterial colonies are beneficial for the synthesis of metabolites, such as antibiotics

The form is influenced by the amount of vaccination pH、 The influence of factors such as the composition of the culture medium and air shear force

The air lift fermenter has no mechanical stirring and low shear force, which is suitable for maintaining the integrity of mycelium and preventing mycelium breakage

2、 Harvesting and post-processing

After the cultivation is completed, stop gas and cool down

Collect bacterial cells or metabolites through filtration, centrifugation, and other methods

Downstream processing (extraction, concentration, drying, etc.)

Summary: Advantages of using an airlift bioreactor to cultivate filamentous bacteria

No mechanical stirring, reducing mycelial damage

Gentle fluid circulation promotes oxygen distribution

Suitable for large-scale continuous fermentation and automatic control

Challenge and Optimization Strategy

Although air lift fermenters perform well in cultivating filamentous bacteria, there are also some challenges:

More foam: filamentous bacteria often metabolize to produce foam, which needs to add defoamer or optimize gas flow rate.

Oxygen transfer limitation: In high-density cultivation, it is still necessary to optimize the ventilation rate or use oxygen rich gas.

Reunion issue: Excessive group gatherings result in insufficient internal nutrient and oxygen transfer, which can be addressed through vaccination doses pH、 Shear condition regulates the morphology of bacterial cells.

Summarize

Airlift fermenters are highly suitable for large-scale liquid fermentation cultivation of filamentous bacteria due to their mild hydrodynamic environment and excellent oxygen transfer performance, especially in the industrial production of antibiotics, enzyme preparations, and other secondary metabolites.