Cell suspension culture technology refers to the large-scale and high-efficiency culture technology of animal cells used in biological products under artificial conditions through the use of bioreactors. With the continuous innovation and development of biotechnology, animal cell suspension culture technology has been widely used in the large-scale culture of viruses, which has very efficient production efficiency, and also has the advantages of high quality and biosafety and easy control.

The vast majority of cells used in vitro in suspension culture are of animal origin, so this technology has been well used in the preparation of veterinary vaccines.

1. Selection and suspension of acclimated animal cell lines

Safety, efficacy and cost control are the most important considerations in the production of animal vaccines, which can improve the production efficiency of veterinary vaccines and ensure the reliability of the quality of biological products.

In the production process, it is of great significance to do a good job in the selection and domestication of animal cell lines to optimize the above requirements. Because of the interaction between the same cell and the virus ready for expansion, it is important to reciprocal adaptation to the target virus before applying a cell line for large-scale vaccine production. At the same time, the growth characteristics of the selected cells are decisive for the ability to perform large-scale proliferation cultures, and which process to use for proliferation cultures, as the same cells are not equally sensitive to viruses in different culture states. On the other hand, this technology has high requirements for the reproductive efficiency, viability and biological stability of suspension cells, and acclimation is the primary task of cell suspension, and it is best to maintain the viability of cells above 90%.

2. Selection of the most appropriate medium

Selecting the right medium is the most critical link in the cell suspension culture technology. In general, the growth of animal cells must have the nutrient of serum, but due to the complexity of the composition of serum, and the disadvantages of high price and large differences in serum composition between different batches, this medium is difficult to apply in actual vaccine production.

At present, with the continuous innovation of technology, this serum medium has been gradually replaced by serum-free medium, which effectively reduces the situation that the serum medium is easy to be contaminated, and also reduces the cost of production to a certain extent. However, due to the high selectivity of cell culture to the medium, a single serum-free medium cannot be applied to the culture of a variety of cell lines, which promotes the rapid development of personalized blood-free medium, and an appropriate amount of specific bioactive substances such as transferrin, insulin or fibronectin can be added to the serum-free medium to promote the rapid reproduction and growth of animal cells.

3. Choosing the right bioreactor

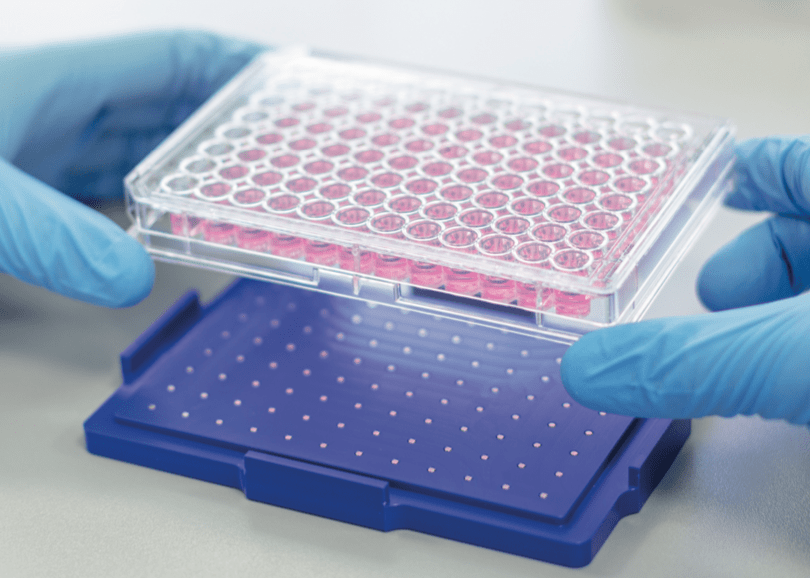

As the key equipment of the cell suspension culture technology center, the bioreactor mainly uses cells or enzymes as biological catalysts, and can also provide a sterile environment for the growth and reproduction of cells.

The biggest advantage is the ability to scale up gradually, and since the cost of vaccine production is affected by the size of the cells produced, the choice of bioreactor has a direct impact on the cost of vaccine production. The requirements for bioreactors in vaccine production typically include the following: high production efficiency, high reliability, low production costs, strong safety performance, strong activity, easy control of quality and recovery, and high cell density. The following kinds of bioreactors are widely used in actual production, namely: flow-bed bioreactors, airlift bioreactors and rotary cell culture systems.

4. Selection of production process

The choice of production process determines the final processing process of cell suspension culture technology, which can be divided into the following five modes according to the different culture methods: batch, fed-batch, semi-continuous, continuous and perfusion operation. Different production processes have their own characteristics and advantages, and also have their own corresponding types of bioreactors, which can be flexibly optimized according to the different cultured cells and the types of vaccines produced in the actual production process.

About BaiLun Biotechnology Co., Ltd:

BaiLun Biotechnology Co., Ltd. stands as a leading supplier and premier technical service provider, specializing in the provision of comprehensive bioreactor systems and advanced control solutions. Our extensive product line encompasses a wide array of offerings, ranging from bioreactors (fermenters) to animal cell bioreactors, biological shakers, and control systems tailored for bioprocessing applications. With a capacity spanning from 0.1L to 1000KL, we are committed to fostering the growth of China’s bioreactor industry on a global scale.

At BaiLun, we boast a seasoned team of engineers equipped with profound expertise in fermentation processes, biochemical equipment, and chemical technology. Moreover, we actively engage nationally renowned experts and scholars as technical consultants, ensuring the robust technological underpinnings of our products. Central to our ethos is a relentless pursuit of product innovation and technological leadership, all geared towards guaranteeing utmost customer satisfaction. We hold ourselves accountable to prioritize customer benefits, embodying this commitment as the cornerstone of Bailun Company’s core values.

Our diverse product portfolio is meticulously crafted to cater to the multifaceted demands of our clientele. From inception, we have upheld the principles of quality paramountcy, customer-centricity, and integrity-driven operations. It is our unwavering dedication to meeting the evolving needs of our customers that propels us forward. Embracing the tide of economic globalization, we extend a genuine invitation to collaborate with enterprises worldwide, aiming for mutual prosperity and success.

The spirit of BaiLun encapsulates a dedication to customer-centricity, a pursuit of excellence in quality, a commitment to fairness and integrity, and an unwavering drive for continuous improvement and innovation.

Contact Us:

Add:6848# Liuxiang Rd., Jiading, Shanghai, China

Contact Person: Maddie

Email:[email protected]

Phone:+86-134-7276-8163 (WhatsApp)

Website: https://fermentorchina.com/