Fermenter Technical Parameters:

| Parameter | Description |

| Total volume | 5L,10L,15L,20L,30L,50L,100L,200L,500L,1000L, 5KL, 10KL etc. |

| Working volume | 30%~70% |

| Tank | Inside electrolytic polishing, precision: 0.2-0.4um.

Diameter and height ratio 1:1.5 |

| Stirring system | Magnetic drive, low shear mixing blades. Stir speed: 30~300rpm |

| Sterilization | Sterilize in place (SIP), auto control by program |

| Clean | Clean in place by spray ball |

| Gas control | Provision for mixing at least four gases (Air, Oxygen, Nitrogen and CO2)

Auto control by mass flow meter. Air flow 1vvm, O2/N2/CO2 0.1vvm. |

| Feeding | Automatically feeding by peristaltic pump |

| Anti-foam control | Automatically add antifoamer by peristaltic pump |

| Temperature control | Auto-control, electric heating range: water source add 5℃ to 70℃ |

| PH control | PH 2.00-12.00±0.1, auto-control adding acid/base by peristaltic pump, pH sensor from Hamilton/Mettler, Switzerland. |

| Do control | 0-150±3% displaying precision 0.1%, DO sensor from Hamilton/Mettler, Switzerland. DO coupling with agitation, oxygen. |

| Sampling valve | Can sterilization separately, manual |

| Harvest | Zero dead zone bottom valve, can sterilization separately, manual |

| Weight system | Mettler-Toledo, Switzerland |

| Pressure | Auto control, BD Germany pressure transmitter or Lambert differential pressure liquid level gauge. |

| Exhaust | Have condenser before exhaust, control by diagram valve / Proportional control valve. |

| Control parameters | 10 or 15 inch touch screen, Siemens PLC with control parameters (stirring, pH, DO, temperature, feeding, alarm, gas etc.), data analysis, data record, data output, language(RU/EN/CN) and other customized functions |

| Optional configuration | Remote control, Mass flow meter(auto control gas), exhaust heating, exhaust filter, gas(CO2) exhaust analysis, Level sensor, Turbidity(OD) sensor, ORP sensor, Weight system, Live cell sensor(Biomass), Printing, Siemens touch screen, Double mechanical seal, 4-valves-group for feeding, Bottom valve auto, ASME certificate, CSA certificate, air flow 2vvm, etc. |

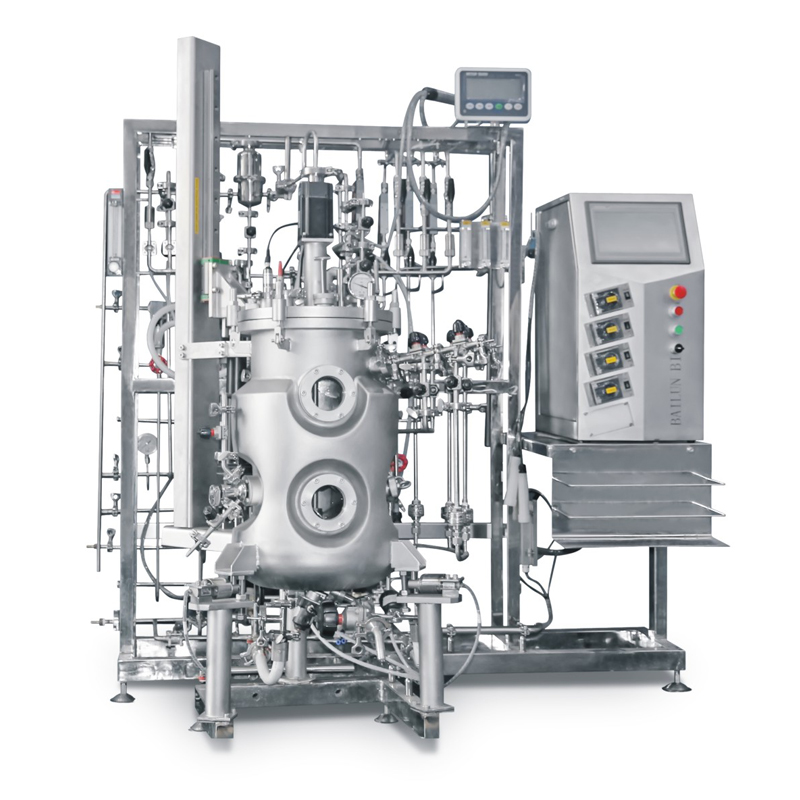

Fermenter Description:

External surface polishing, internal no blind angle; tank material is 316L stainless steel material, clip material is stainless steel 304. Internal tank large visual angle liquid level observation sight glasses, 12V automatic delay Philips safety sight lamp; Two 25mm side holes can connect pH, DO and other sensors, with temperature, pH, DO.

Tank: design pressure 0.3 Mpa Clip: design pressure is 0.3 Mpa, use the optimization diversion design, improve the exchange efficiency and tank temperature uniformity.

Provision for mixing at least four gases (Air, Oxygen, Nitrogen and CO2).

Cooling system with exhaust (organic matter and water of tank will not be lost with the gas exhaust) diaphragm valve control the exhaust not to be infected, specially designed exhaust pipe without the accumulated liquid and bacterium. Using special low shear mixer (turbine) when suspension cell culture.

Siemens S7-200 series PLC + 10-inch tablet computer touch screen display, direct on-site operation (menu type), full English menu and interface; data transmission with the upper computer, sampling and display of tank data, browsing and analysis of system data, Read settings. Control or collect parameters such as pH, DO, tank pressure, temperature, speed, air flow, feed weighing, fermentation broth volume, etc., and can easily calibrate pH and DO electrodes through software; set the initial control state of parameters; have an independent Curve analysis system; directly analyze the historical curve.

Fermenter Application:

Applied for culture of mammal and animal cells through batch feeding or continuous perfusion.

The large-scale culture technology of animal cells (hybridoma cells, CHO cells, insect cels, etc.) and its bioreactor engineeringcan be widely used in research, development and industrial production of antibodies, recombinant protein drugs, viral vaccinesand other biotechnological products.

The large-scale culture technology of animal cells and its bioreactor system consisting ofsuch core technolgies as serum-free suspension culture technology, culture process and bioreactor design amplification andenhancement technology, large-scale high-density feeding and continuous perfusion culture technology, computer real-timemonitoring and control technology of culture process, large-scale and high-efficiency production technology of virus products,etc. have been established.