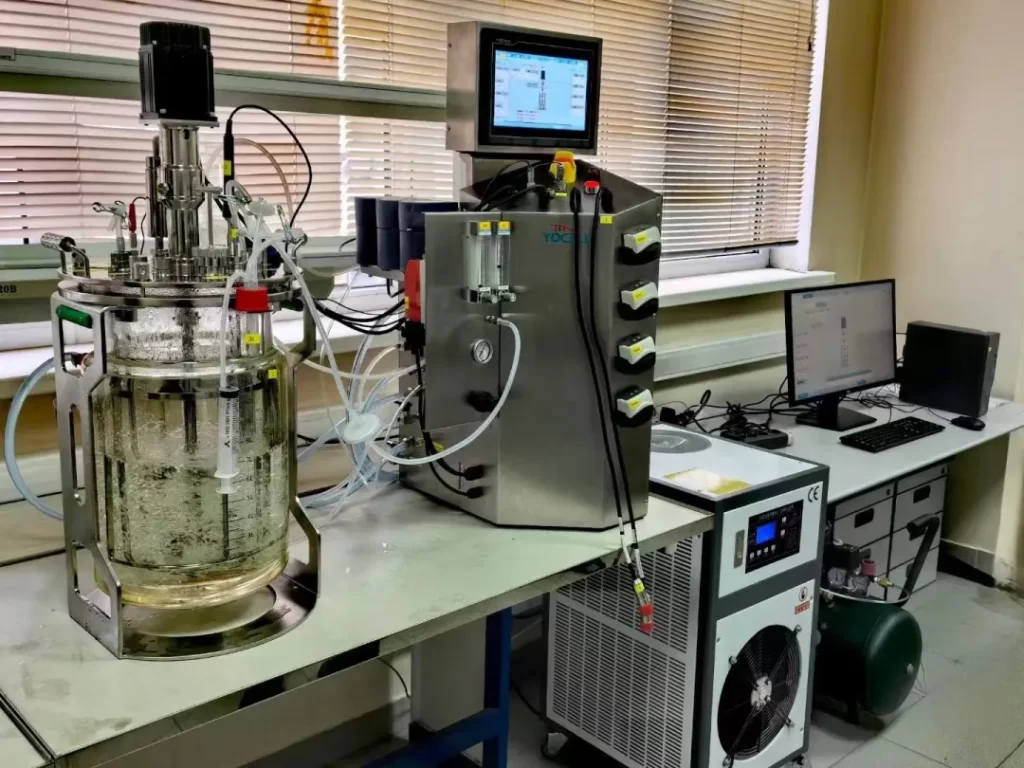

A bioreactor is a type of equipment widely used in life sciences and engineering, which can be used to develop and produce various biological products. With the continuous development of biotechnology, the scale and automation of bioreactors are also increasing. In this article, we will explore the technologies associated with the scale-up and automation control of bioreactors.

1.The need for bioreactors scale-up

The need to scale up bioreactors is mainly due to the following two aspects:

01.Production needs:

As the demand for various types of biologics, such as vaccines, antibodies, growth factors, etc., increases, manufacturers need larger and more efficient bioreactors to increase yield and improve product quality.

02.Research needs:

Some large-scale research projects require large-scale bioreactors to perform experiments, while complex cell cultures in some basic research require larger reactors to increase yields and reduce costs.

2.Challenges of scaling up bioreactors

When a bioreactor scales up to a certain extent, it faces several challenges:

01.Problems with the transport of oxygen and nutrients

As the bioreactor expands, the depth of the liquid level increases, and the rate of oxygen and nutrient transport decreases, resulting in a shortage of oxygen and nutrients inside the bioreactor.

02.Control issues

Large-scale reactors require a higher level of control and monitoring, and process control is challenging.

03.Poor mixing

After the reactor is expanded, the stirring speed will slow down, and the mixing effect will deteriorate, which will affect the homogeneity of the mixing of substances inside the reactor.

Therefore, for the scale of bioreactors, it is necessary to improve and optimize the above challenges accordingly.

3.Solutions for scale-up of bioreactors

The solutions for the scale-up of bioreactors mainly include the following aspects:

01.Design optimization

By optimizing the design of the reactor, such as changing the shape of the reactor and changing the depth of the liquid level, the oxygen and nutrient transport performance in the reactor can be improved.

02.Determine the optimal production conditions

Determine the optimal production conditions, such as temperature, stirring speed, air intake, etc. At the same time, advanced measurement and control technology is adopted to realize the automatic control of the reaction process.

03.Improves mixing performance

The use of high-efficiency mixers or agitators, such as propellers, scrapers, bubbles, etc., can improve the homogeneity of the mixing of substances inside the reactor.

04.Advanced fermentation technology is used

The use of advanced fermentation technology, such as batch production, gradual dropwise addition of nutrients, control of air intake rate, etc., can avoid the problems caused by the expansion of the bioreactor and ensure production efficiency and quality.

4.Application of automation control in bioreactor production

With the continuous development of science and technology, automation control is becoming more and more important in the production of bioreactors. Automatic control can effectively improve the production process, improve production efficiency and product quality. The automated control of bioreactors usually includes the following aspects:

01.Measurement and control systems

Various parameters in the reactor, such as temperature, pressure, pH, dissolved oxygen, etc., are measured by installing sensors and measuring instruments in the reactor for real-time monitoring and control of the production process.

02.Control algorithms

The control algorithm is the key to the automation control process of the bioreactor. Commonly used control algorithms include PID control, model predictive control, etc., which are used to control parameters such as flow velocity and stirring intensity in the reactor.

03.Machine learning algorithms

In recent years, machine learning algorithms have been widely used in the automated control of bioreactors. It mainly predicts the state of the reactor by training the model, and automatically adjusts the control parameters according to the prediction results to achieve the best control effect.

5.Summary:

Scale-up and automation of bioreactors have become important issues in modern life sciences and engineering. By improving the design of the reactor, optimizing the production process, improving the mixing performance, and improving the control algorithm, the challenges of reactor scale-up can be effectively solved, and the production efficiency and product quality can be improved. At the same time, the introduction of machine learning technology can bring new ideas and possibilities for reactor automation control, and further promote the development of bioreactor technology.

About BaiLun Biotechnology Co., Ltd:

BaiLun Biotechnology Co., Ltd. stands as a leading supplier and premier technical service provider, specializing in the provision of comprehensive bioreactor systems and advanced control solutions. Our extensive product line encompasses a wide array of offerings, ranging from bioreactors (fermenters) to animal cell bioreactors, biological shakers, and control systems tailored for bioprocessing applications. With a capacity spanning from 0.1L to 1000KL, we are committed to fostering the growth of China’s bioreactor industry on a global scale.

At BaiLun, we boast a seasoned team of engineers equipped with profound expertise in fermentation processes, biochemical equipment, and chemical technology. Moreover, we actively engage nationally renowned experts and scholars as technical consultants, ensuring the robust technological underpinnings of our products. Central to our ethos is a relentless pursuit of product innovation and technological leadership, all geared towards guaranteeing utmost customer satisfaction. We hold ourselves accountable to prioritize customer benefits, embodying this commitment as the cornerstone of Bailun Company’s core values.

Our diverse product portfolio is meticulously crafted to cater to the multifaceted demands of our clientele. From inception, we have upheld the principles of quality paramountcy, customer-centricity, and integrity-driven operations. It is our unwavering dedication to meeting the evolving needs of our customers that propels us forward. Embracing the tide of economic globalization, we extend a genuine invitation to collaborate with enterprises worldwide, aiming for mutual prosperity and success.

The spirit of BaiLun encapsulates a dedication to customer-centricity, a pursuit of excellence in quality, a commitment to fairness and integrity, and an unwavering drive for continuous improvement and innovation.

Contact Us:

Add:6848# Liuxiang Rd., Jiading, Shanghai, China

Contact Person: Maddie

Email:[email protected]

Phone:+86-134-7276-8163 (WhatsApp)

Website: https://fermentorchina.com/