“Synthetic life, design life” is an important mission of synthetic biology and biomanufacturing, through on-demand design and chemical reconstruction of artificial genomes, to achieve the precise construction of artificial cell factories.

At present, cell factories are faced with bottlenecks such as complex metabolic networks, lack of rational design, high cost of trial and error, and long cycle of chassis biological transformation, which limit the application of cell factories.

The integration of the three will build a next-generation flexible, intelligent and automated cell factory, create a new paradigm of R&D of molecular biosynthesis, greatly accelerate the cycle iteration of design, synthesis, testing and optimization, and realize the on-demand design and rapid production of high-value target molecules.

Cell factory flexible technology

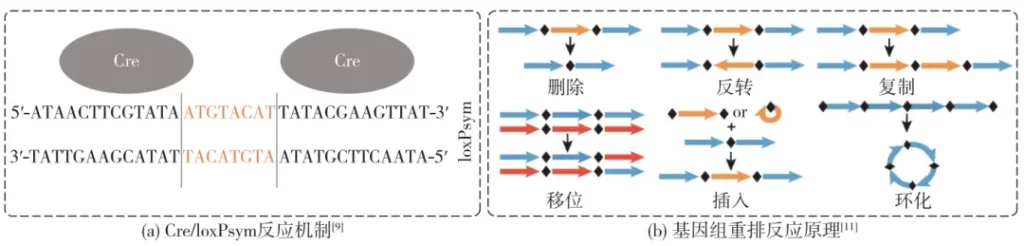

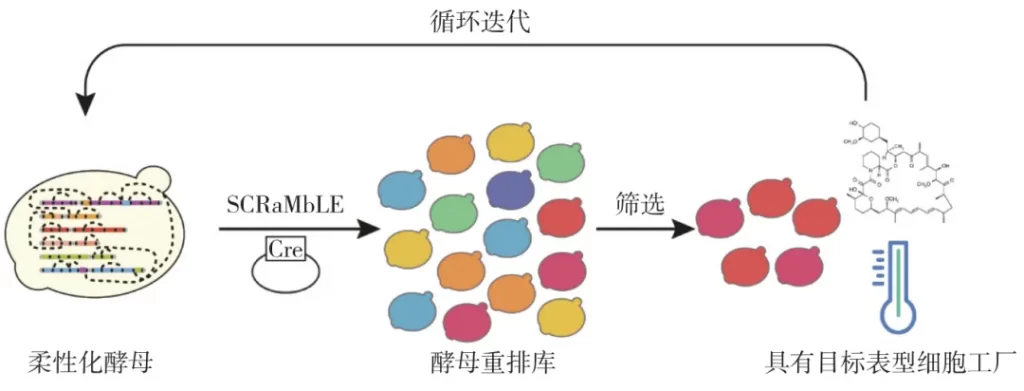

The flexibility of cell factories mainly refers to the ability of a cell genome to undergo a wide range of structural variations and produce genotype diversity. With the continuous progress and development of synthetic biology, the de novo synthesis of large DNA fragments and even the entire genome has been gradually realized. For example, the goal of the International Project on Synthetic Yeast Genomes is to obtain a highly adaptable, flexible and versatile Saccharomyces cerevisiae genome. In the Sc2.0 project, loxPsym loxPsym is inserted at the end of the 3′ (3′UTR) of all non-essential genes, and upon Cre recombinase, various rearrangement reactions including deletion, inversion, replication, and translocation occur between these loxPsym sites , resulting in a rearrangement library containing a diverse genotype.

The SCRaMbLE system greatly promotes the flexibility of yeast and can rapidly drive structural rearrangement of the genome. Genotypic diversity can lead to phenotypic diversity, and traits desired for cell factories can be obtained by one round or iterative of SCRaMbLE and screening.

Flexible application of cell factory

Genome-wide scale-mediated loxPsym-mediated genome flexibility can generate rich genomic structural variation and obtain yeast strains with a variety of genotypes and phenotypes. Next, we will focus on case studies to illustrate how cell flexibility can be used to obtain excellent cell factory strains with growth adaptability and increased product yield.

1.Flexible cells improve the growth adaptability of the strain

Flexible cell technology has established effective methods to enhance the cell’s tolerance to the environment (e.g., high temperature, acetic acid, alkaline, ethanol or xylose, etc.) and drug resistance (e.g., rapamycin, hygromycin B or caffeine), which can increase the potential of cell factories in industry.

Heat tolerance is one of the main limiting factors for the industrial production of ethanol by yeast. Flexible induction of haploid and diploid yeast can significantly increase the tolerance of strains to high temperatures. Not only that, but the drug tolerance of cells can also be enhanced through cell flexibility.

2.Flexible cells increase the yield of products in cell factories

Flexible cell technology not only improves the strain’s native phenotype (tolerance), but also improves the strain’s production of metabolites of heterometabolic pathways. Heterologous metabolic pathways can be introduced into synthetic yeast through free plasmids or integration into the yeast genome. Flexibility induction can alter the metabolic network (e.g., deletion, replication, reversal, or translocation of yield-related genes) by producing a large number of structural changes, thereby increasing the yield of the target product.

Carotenoids are important antioxidants that can be used to screen for yield-boosting strains through color changes. Purple bacillin is another heterologous metabolite that is easy to screen.

The application of flexible cell technology to the development of high-quality cell factories with industrial application value is a promising approach. The advantage of cell flexibility is that a diverse genetic pool with different structural variations can be obtained in just a few days.

More importantly, because the principle of mutation in flexible cells is different from other methods, the SCRaMbLE system is orthogonal to these existing genomic evolution techniques. As a result, flexible cell technology can be combined with other techniques to speed up the screening process. In addition, flexible synthetic chromosomes can also be transferred to wild-type strains by CRISPRCas9 technology, which can extend the application of flexible cells by passing on the special phenotype produced by flexible cells to other wild-type yeasts.

Cell factories are intelligent

The elements and modules of existing cell factories mainly rely on simple modifications or mutational screening of natural organisms, and the rapid development of AI technology in recent years has shown great potential in the design of elements and modules of cell factories such as DNA, RNA, and protein. Although data-driven intelligence methods can find patterns in large amounts of data, it is not only difficult to achieve efficient search of exponential design space for complex biological systems, but also cannot ensure the safety and controllability of design results.

To overcome these issues, a combination of data-driven and knowledge-driven approaches is crucial. Artificial cell design needs to integrate traditional experimental data, biological rules and expert knowledge to achieve comprehensive development from local modification of gene elements to new creation, from local optimization of gene network to overall adaptation, from local replacement of genome to de novo design and synthesis, and from passive observation of cell function to precise control. The advantage of dual drive is the combination of data-driven and knowledge-driven. While data-driven approaches can leverage large-scale data for pattern recognition and discovery, they may ignore biological rules and constraints.

The knowledge-driven approach, on the other hand, is based on biological rules and expert knowledge, which can guide the design and ensure biologically feasible implementation. By combining the best of both worlds, researchers can take full advantage of the richness of the data and the guidance of knowledge to achieve efficient and accurate screening and design, and drive the future development of artificial cell design.

The flexible technology of cell factories based on artificial genome synthesis generates huge data sets (genomics, transcriptomics, proteomics, metabolomics, and protein interaction information, etc.) in the process of actual experiments. At the same time, in order to realize the on-demand customization and construction of cell factories, it is necessary to comprehensively develop the theory of systematic and cross-scale intelligent design of synthetic biological systems at the levels of gene elements, gene networks, and cell states.

Combining the flexibility and intelligence of cell factories is one of the future trends, and focusing on the intelligent on-demand design of new gene elements, the intelligent adaptation and optimization of artificial gene networks, and the intelligent and precise control of cell status and function, so as to realize the intelligent and controllable design of artificial cells, and provide important theoretical basis and method support for the creation of powerful, accurate and reliable synthetic biological systems.

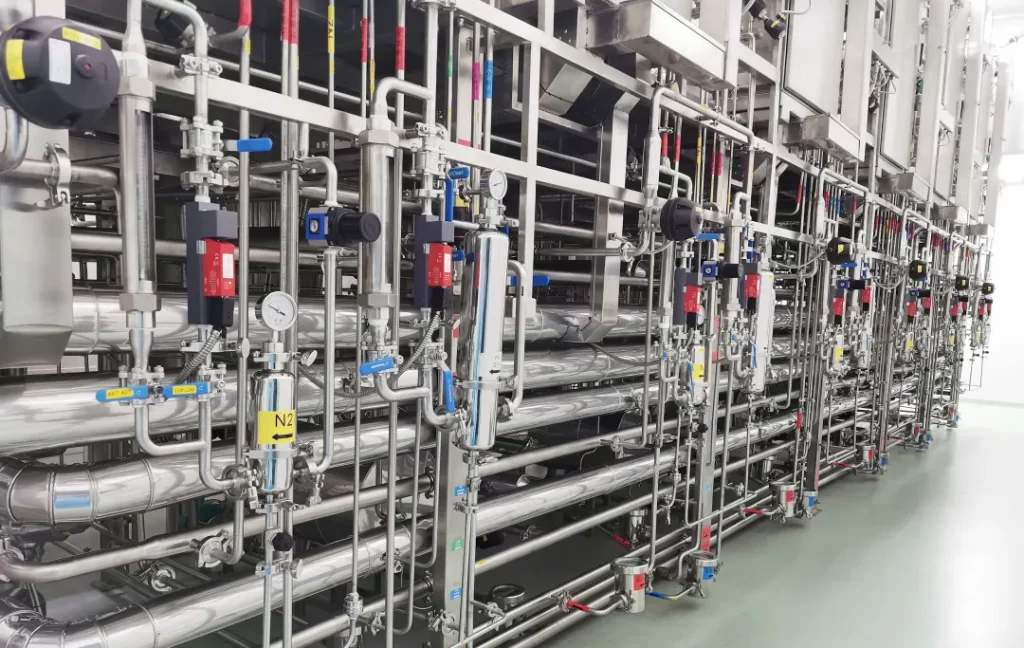

Cell factory automation

The traditional cell factory transformation and screening face bottlenecks such as complex metabolic network, lack of rational design, high cost of trial and error, and long cycle of chassis biological transformation.

This kind of automation can improve the stability of experimental operations, and it can solve the problems of cumbersome, time-consuming, error-prone and difficult-to-scale compared to traditional technologies, thus greatly improving the efficiency of R&D.

At the same time, the cell factory flexibility process produces strains with many intermediates, which requires a lot of time and effort to perform complex genetic manipulation. It is foreseeable that automation and high-throughput quantification have great application value in cell modification and screening.

However, cell factory automation is a cross-cutting field involving multiple disciplines such as mechanical engineering, automation, computing, and life sciences, which requires the joint efforts of all parties to develop in the direction of a higher degree of automation.

About BaiLun Biotechnology Co., Ltd:

BaiLun Biotechnology Co., Ltd. stands as a leading supplier and premier technical service provider, specializing in the provision of comprehensive bioreactor systems and advanced control solutions. Our extensive product line encompasses a wide array of offerings, ranging from bioreactors (fermenters) to animal cell bioreactors, biological shakers, and control systems tailored for bioprocessing applications. With a capacity spanning from 0.1L to 1000KL, we are committed to fostering the growth of China’s bioreactor industry on a global scale.

At BaiLun, we boast a seasoned team of engineers equipped with profound expertise in fermentation processes, biochemical equipment, and chemical technology. Moreover, we actively engage nationally renowned experts and scholars as technical consultants, ensuring the robust technological underpinnings of our products. Central to our ethos is a relentless pursuit of product innovation and technological leadership, all geared towards guaranteeing utmost customer satisfaction. We hold ourselves accountable to prioritize customer benefits, embodying this commitment as the cornerstone of Bailun Company’s core values.

Our diverse product portfolio is meticulously crafted to cater to the multifaceted demands of our clientele. From inception, we have upheld the principles of quality paramountcy, customer-centricity, and integrity-driven operations. It is our unwavering dedication to meeting the evolving needs of our customers that propels us forward. Embracing the tide of economic globalization, we extend a genuine invitation to collaborate with enterprises worldwide, aiming for mutual prosperity and success.

The spirit of BaiLun encapsulates a dedication to customer-centricity, a pursuit of excellence in quality, a commitment to fairness and integrity, and an unwavering drive for continuous improvement and innovation.

Contact Us:

Add:6848# Liuxiang Rd., Jiading, Shanghai, China

Contact Person: Maddie

Email:[email protected]

Phone:+86-134-7276-8163 (WhatsApp)

Website: https://fermentorchina.com/