About 2/1 of the world’s total annualCO2 emissions are fixed into organic matter by algae through photosynthesis. Compared with terrestrial higher plants, microalgae photosynthetic carbon sequestration has many unique advantages: firstly, microalgae photosynthesis efficiency is higher and the growth rate is faster than that of plants, and secondly, microalgae culture does not occupy arable land and freshwater resources, and can even use wastewater and industrial flue gas cultivation. The carbon content in microalgae is close to 50%, which is mainly derived from immobilizedCO2, and the production of 1 kg of microalgae biomass (dry weight) can fix about 1.8 kg ofCO2. More importantly, the microalgal biomass produced is regarded as a sustainable source of bioenergy and biochemical products, and maximizing the value of microalgae biomass resources through the concept of biorefinery has gradually become a research hotspot worldwide.

Microalgae biomass contains a variety of bioactive substances with medicinal and nutritional value, such as polyunsaturated fatty acids, carotenoids, vitamins, etc., and microalgae biomass can also be used to produce a variety of bioenergy as a substitute for fossil energy, such as biohydrogen, bioethanol and biodiesel. In addition, microalgae are not only natural bait for aquaculture animals, but also serve as a high-quality protein source for human food, alleviating food security issues.

However, the large-scale cultivation and commercial application of microalgae still face the challenges of low actual yield and high cultivation cost. The theoretical maximum solar use efficiency of microalgae in the process of biomass synthesis through photosynthesis is 8%~10%, and the temperature of leaves is 30 °C and the concentration ofCO2 is 387 mL/m3,C3 andC4The theoretical maximums of solar conversion rates for plants are 4.6% and 6%, respectively. However, in most cases, the actual light energy utilization rate of continuous microalgae culture in the laboratory is only about 3%, and the conversion rate of large-scale culture is even lower. This indicates that the culture of microalgae is far from reaching its photosynthetic potential, and there is still a huge room for optimization in terms of photosynthetic carbon sequestration capacity and the potential of cultivation technology.

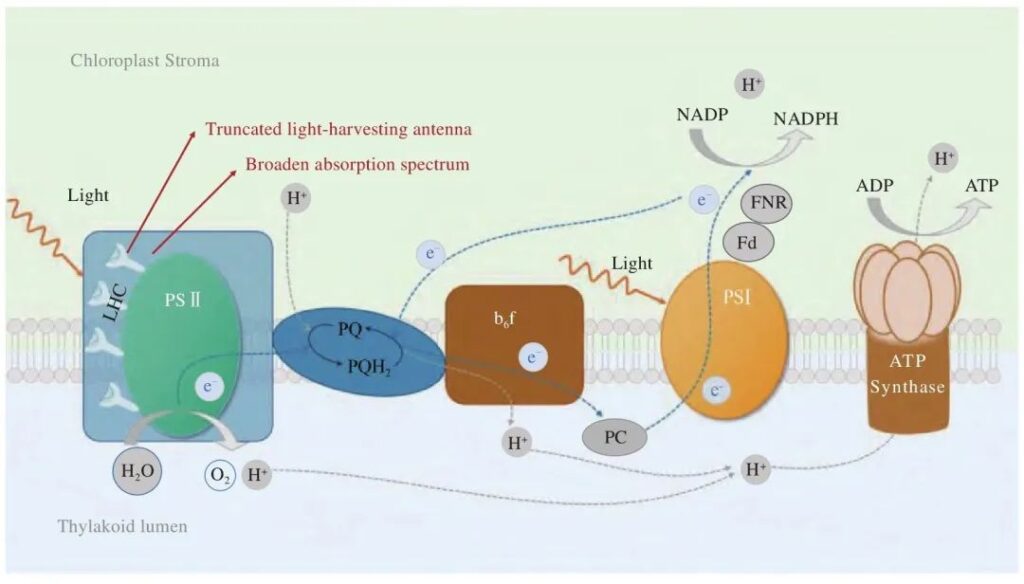

1.Optimization of photoreaction stages in microalgae photosynthesis

Figure 1 is a schematic diagram of the photoreaction stages of microalgae. Similar to higher plants, microalgae capture light energy through different types of light-harvesting antennas (light-harvesting complexes) and conduct it to the reaction center of photosystem II., where the oxidized water releases oxygen, produces hydrogen ions and electrons, and ultimately produces ATP and NADPH. There is an electron transport chain between photosystem II. and I., which contains electron acceptors such as plastid quinone and cytochrome b6f (Cyt b6f). Truncating the light-harvesting antenna and improving the light energy use efficiency are the most commonly used methods for the modification of the photoreaction stage of microalgae.

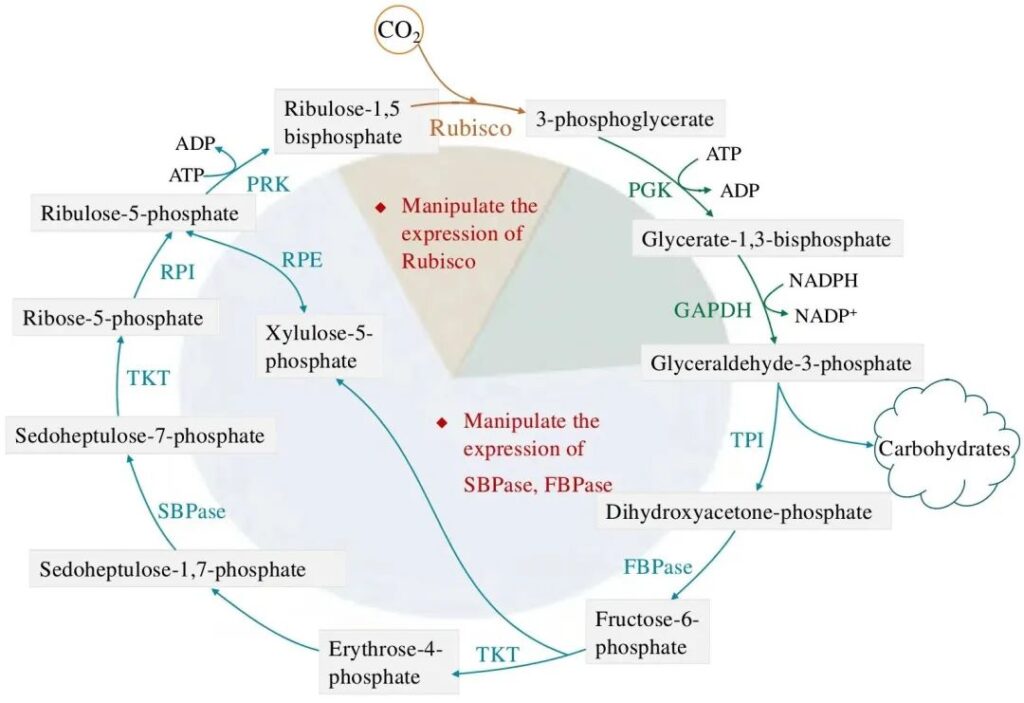

2.Optimization of the dark reaction phase of microalgae photosynthesis

2.1 Modification of ribulose-1,5-bisphosphate carboxylase/oxygenase

In the CBB cycle, ribulose-1,5-bisphosphate carboxylase/oxygenase (Rubisco) is responsible for catalyzing the reaction of 1 moleculeCO2 with 1 molecule Ribulose-1,5-bisphosphate (RuBP) to generate 2 molecules of 3-phosphoglycerate, which is considered to be the rate-limiting step of the entire cycle. Rubisco is the most abundant protein in the biosphere and forms a bridge between inorganic carbon and living organisms. But at the same time, Rubisco is also considered to be a very inefficient catalyst. Therefore, in higher plants, Rubisco has also been regarded as the primary target of photosynthetic modification, which has received great attention and research. The structure of Rubisco in cyanobacteria, diatoms, and green algae is very similar, consisting of 3 large subunits and 8 small subunits. The large and small subunit genes of the green algae Rubisco are present in the chloroplast and nuclear genomes, respectively, while the genes encoding the large and small subunits of diatoms are located in the chloroplast genomes. Microalgae have always been regarded as excellent “donors” of Rubisco, and the use of Rubisco as a source of microalgae to replace Rubisco in higher plants is regarded as a potential means to improve the photosynthesis efficiency and biomass of higher plants. However, due to the complex assembly mechanism of Rubisco, the heterologous expression of the microalgae Rubisco in plants did not achieve satisfactory results

2.2 Construct photorespiratory branches

Rubisco’s oxygenation produces the toxic metabolite 2-phosphoglycolic acid (2-PG), which needs to be recycled through the photorespiration pathway, but the photorespiration process requires the consumption of ATP and NADPH, and the release of immobilizedCO2 andNH3; 2 molecules of 2-PG are converted to 1 molecule of 3-phosphate glyceric acid (3-PGA) through the photorespiration pathway, and the whole process consists of distributed in chloroplasts, peroxisomes, Nine enzymatic steps in the mitochondria and cytoplasm are completed, and it is estimated that photorespiration can release up to 9/1 of the immobilizedCO4, resulting in a huge waste of C and N. However, the photorespiration process recovers 2% of C for cellular metabolism from 2 molecules 2-PG, which plays a very important role in cellular metabolism, therefore, theoretically, constructing a new photorespiration branch to avoid the waste ofCO75 andNH2 or increase the recovery capacity of releasingCO3 can improveCO2to increase biomass production rate. The feasibility of this scheme has been successfully demonstrated in the model organism Arabidopsis thaliana and the oil crop camelina, and the newly constructed photorespiratory branch can help the transformed strain significantly increase the biomass production rate.

2.3 Transformation of carbon enrichment mechanism

UnlikeC3 plants, most microalgae andC4 plants have a carbon concentration mechanism (CCM) to cope with lowerCO2 concentrations in the aquatic environment. In cyanobacteria, Rubisco is sealed in carboxysomes, while the eukaryotic microalgae Rubisco is mainly present in chloroplast protein nuclei, and the concentration ofCO2 around the active site of Rubisco can reach more than 1000 times that of the surrounding environment through CCM. Carbonic anhydrase (CA) is a key enzyme involved in CCM and is responsible for catalyzing reversible betweenHCO3− andCO2. CCM in microalgae is usually an inducible mechanism that regulates the expression level of CCM through the perception of surroundingCO2 concentrations. Large-scale cultivation of microalgae often usesCO2 concentrations well above the air, which can lead to the shutdown of the CCM.

In summary, many important pioneering progress has been made in the transformation and optimization of microalgae photosynthetic systems by means of truncating the light-harvesting antenna, increasing the light-harvesting capacity and light energy utilization, transforming the CBB cycle and CCM, and constructing the photorespiratory branch. However, the overall progress lags behind the transformation and optimization of photosynthesis pathways of higher plants, especially cash crops, resulting in the unrealized potential of carbon sequestration by microalgae. Through the mining of excellent photosynthetic elements, regulatory factors and the construction of new pathways, the limitation of bottleneck steps can be effectively relieved and the energy balance between light and dark reactions can be realized. In addition to being regulated by light, photosynthesis is also regulated by the consumption efficiency of the final product, which indicates that it is necessary to simultaneously carry out the modification of photosynthesis-related metabolic pathways at the cellular level. With the rapid development of synthetic biology, it has laid a foundation for the design and construction of high-efficiency carbon sequestration microalgae engineering strains using microalgae as photosynthetic carbon sequestration chassis organisms. Synthetic biology methods and concepts can be used to design or synthesize photosynthetic systems with higher light energy efficiency and carbon sequestration efficiency, resistance to photodamage, and production of less reactive oxygen species, regardless of species limitations.

About BaiLun Biotechnology Co., Ltd:

BaiLun Biotechnology Co., Ltd. stands as a leading supplier and premier technical service provider, specializing in the provision of comprehensive bioreactor systems and advanced control solutions. Our extensive product line encompasses a wide array of offerings, ranging from bioreactors (fermenters) to animal cell bioreactors, biological shakers, and control systems tailored for bioprocessing applications. With a capacity spanning from 0.1L to 1000KL, we are committed to fostering the growth of China’s bioreactor industry on a global scale.

At BaiLun, we boast a seasoned team of engineers equipped with profound expertise in fermentation processes, biochemical equipment, and chemical technology. Moreover, we actively engage nationally renowned experts and scholars as technical consultants, ensuring the robust technological underpinnings of our products. Central to our ethos is a relentless pursuit of product innovation and technological leadership, all geared towards guaranteeing utmost customer satisfaction. We hold ourselves accountable to prioritize customer benefits, embodying this commitment as the cornerstone of Bailun Company’s core values.

Our diverse product portfolio is meticulously crafted to cater to the multifaceted demands of our clientele. From inception, we have upheld the principles of quality paramountcy, customer-centricity, and integrity-driven operations. It is our unwavering dedication to meeting the evolving needs of our customers that propels us forward. Embracing the tide of economic globalization, we extend a genuine invitation to collaborate with enterprises worldwide, aiming for mutual prosperity and success.

The spirit of BaiLun encapsulates a dedication to customer-centricity, a pursuit of excellence in quality, a commitment to fairness and integrity, and an unwavering drive for continuous improvement and innovation.

Contact Us:

Add:6848# Liuxiang Rd., Jiading, Shanghai, China

Contact Person: Maddie

Email:[email protected]

Phone:+86-134-7276-8163 (WhatsApp)

Website: https://fermentorchina.com/