Overview of photobioreactors for microalgae cultivation

Microalgae can effectively use light energy, carbon dioxide and inorganic salts to synthesize proteins, fats and a variety of high value-added bioactive substances. Microalgae can be cultivated to produce healthy food, food additives, animal feed, biofertilizers and other natural products.

The way the microalgae grow determines the importance of light in the bioreactor. Except for some completely autotrophic microalgae that can be cultured under no-light conditions (in this case, the reactor can use a traditional microbial fermenter), most microalgae must be cultured in photobioreactors.

One of the keys to the design and structure of photobioreactor is to provide a high ratio of light surface area to volume, with the purpose of improving light transmittance and the utilization rate of light energy by algae cells;

Another key to the design is to select an appropriate circulation device to reduce the damage of shear force to algae cells; in addition, the dissolution of carbon dioxide and gas-liquid mass transfer, the accumulation and timely discharge of dissolved oxygen during photosynthesis and oxygen release, and other gas transfer efficiency and light source quality The choice of bioreactor and form will have a great impact on the efficient cultivation of microalgae in photobioreactors.

At present, there are two main methods of microalgae culture: open large tank culture and closed bioreactor culture.

Open culture generally uses cement tanks. Carbon dioxide can be supplied artificially or rely on natural exchange with air, and can be replenished by artificial stirring to dissolve carbon dioxide in the air. The most prominent features are simple construction, low cost and easy operation, but Open culture has the disadvantages of being susceptible to contamination and unstable culture conditions.

In addition to being able to collect light sources, closed reactors are similar to traditional bioreactors for microbial fermentation in many other aspects. They have stable culture conditions, can be operated aseptically, and are easy to carry out high-density culture. They have become the future development direction.

At present, there are many forms of closed reactors, such as fermenter type, tube type and plate type photobioreactors.

Fermentation Tank Photobioreactor

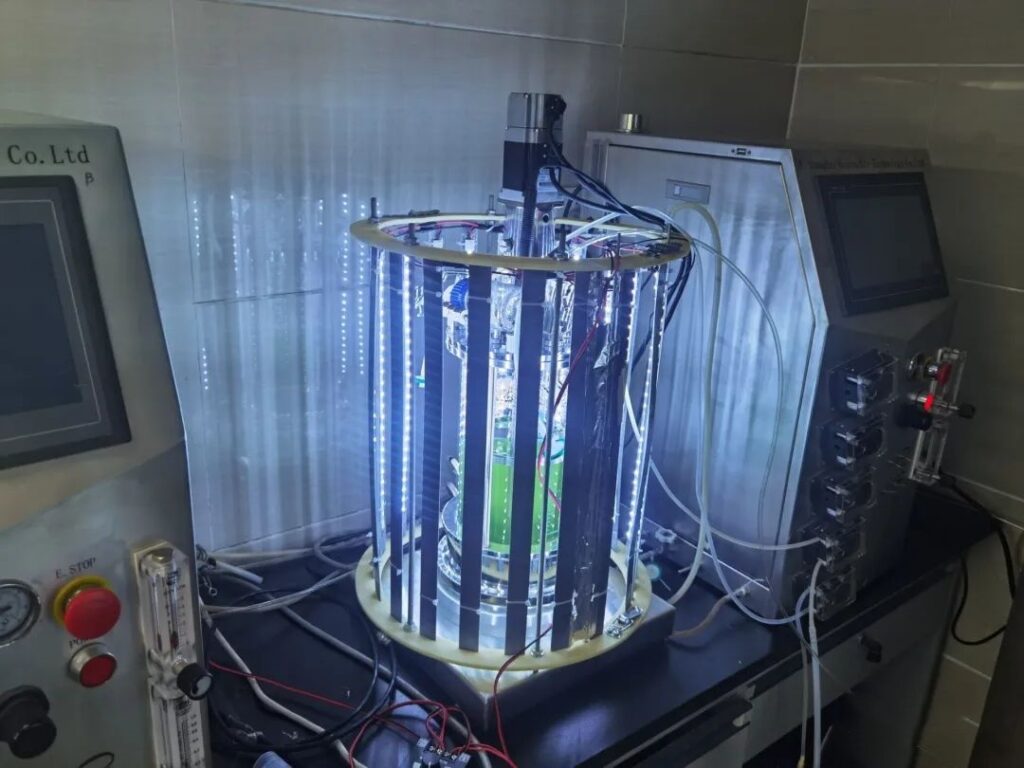

The fermentation tank photoreactor is based on the traditional microbial fermentation tank and adds light for microalgae cultivation.

Small reactors can be made of light-transmitting materials such as glass and use external light sources. Mixing methods also include mechanical stirring, air lift and bubbling. It is characterized by a high culture volume within a limited floor space, which is of great significance for cultivating microalgae using existing fermentation technology.

For fermenter-type photoreactors, the general illumination area to volume ratio is small. How to increase the illumination area to volume ratio without affecting other performance is the main problem that needs to be solved.

Balun 1500L fermenter built-in light source photobioreactor algae bioreactor

Tubular photobioreactor

Tubular photoreactors use transparent pipes to cultivate algae in factories with the help of external lighting conditions.

The design and operation theory of tubular photoreactors was first proposed by Prit et al. Later, it was studied and applied by many people, and developed into various forms such as vertical tube type, tilt-adjustable tube type, horizontal tube type, etc.

Plate photobioreactor

Plate photobioreactors are mainly made of transparent glass or plexiglass plates. According to changes in sunlight intensity and incident direction, the most suitable lighting direction can be adjusted to increase the light transmittance, and can be maintained by adjusting different reactor thicknesses. The short light path ensures that the effective liquid layer is fully exposed to light, and the mixing intensity can also be adjusted, making it easy to achieve high-density culture.

The reactor mainly consists of a light source, circulation device, plate reactor, temperature control system, culture medium and carbon dioxide supply system.

The reactor uses sunlight or halogen lamps. The light intensity is controlled by adjusting the distance between the light source and the reactor or the incident direction of light radiation. The mixing system in the reactor includes airlift mixing, bottom bubbling mixing or mechanical stirring.

Balun 10L glass algae bioreactor with external light source

Summary

Among the above-mentioned reactors, transparent reactors generally use external lighting, the internal structure of the reactor is relatively simple, and the diameter of the reactor is small. If the fermentation tank type is used, the reactor volume is small, which has certain limitations.

In addition to ensuring that the light intensity meets the growth needs of microalgae, internal lighting must also consider the impact of high-temperature sterilization, sealing requirements, mixing requirements, heat dissipation, etc. of the reactor. The installation, protection, and light transmission requirements of the light source are relatively high. Currently widely used light sources, such as sunlight, metal halide lamps, cold incandescent lamps, etc., have many disadvantages. In order to improve the light energy conversion rate, it is of great significance to choose high light intensity, narrow spectrum, energy-saving, and reliable light sources.

Prospect

Closed photobioreactors have unique advantages over open ones, and their success at commercial scale in microalgae cultivation depends on their production costs.

Modern technology is changing with each passing day. The emergence and use of various new materials and new high-efficiency light sources, coupled with in-depth basic theoretical research, will surely make closed photobioreactors more mature and production costs continue to decrease, so that they can be better applied to industrial production. middle.

About Bailun

Balun has extensive experience in manufacturing various types of reactors and pressure vessels. We have a team of experts in the fields of biological reactions, fermentation processes, machinery manufacturing, and automation control. Our scientific research and technology levels are always at the leading level in China and among the best in the world, providing you with a comfortable, assured, and secure product experience.

Contact Us:

Add:6848# Liuxiang Rd., Jiading, Shanghai, China

Contact Person: Maddie

Email:[email protected]

Phone:+86-134-7276-8163 (WhatsApp)

Website: https://fermentorchina.com/